Analytical services

Analytical Services.

Supporting our customers at every stage in the development process

To make a product work, you need more than ideas and prototypes. You’ll need to make sure it passes specific properties and certain tests. These characteristics originate from both material choice and processing. So, for either development or quality control, you’ll need to identify and quantify these properties. To do so we have an entire analytical service designed to help you achieve that. At the moment our analytical service has following tests with their specific protocols in house but when needed, we design specific tests or reach out to fellow institutes/colleges that can do the test for you.

We use our analytical lab test to discover characteristics or the chemical makeup of the tested sample. Mainly used to do reverse engineering for industries such as pharmaceuticals, food, electronics and plastics, but also highly fitted for failure analysis or identifying contaminants or stains on products. Where work accordingly ISO standards.

With our in-house expertise and machinery, we can offer a wide range of testing services, which we divided in 5 different categories: Physical, Mechanical, Thermal, Optical and Rheological.

Services

-

Physical Tests

-

Relative Density

ISO 1183

The density of a solid is determined on the basis of the upward or downward force that the sample exerts on a body in a liquid.

-

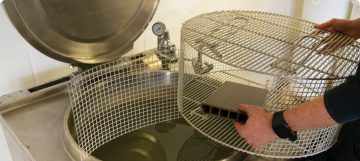

Boiling Test

ISO 60

Test specimens are immersed in boiling distilled water, for prescribed periods. The amount of water absorbed by each test specimen is determined by measuring its change in mass, the change is being expressed as a percentage of the initial mass. If required, the amount of water lost after drying, the test specimens can also be determined.

-

Particle Size

Sieve analysis by air flow. Measures in a range from 25 μm to 2800 μm.

-

Dry Flow

This test method is used to control the flow (dry flow rate) and bulk density of PE powders to the test, this at the service of rotational moulding.

-

Moisture Determination

via Drying

Via infrared moisture content analysis

On the basis of the weight loss for 10 minutes at 110°C the moisture content is determined -> fast method.via TGA – ISO 11358

Thermo-gravimetric analysis

The same principle as above -> more accurate but takes more time. -

Bulk Density

A test to determine the mass per unit of volume, of loose material (powder or granulated) that can be poured from a funnel into a specified design.

-

-

Mechanical tests

-

Tensile Test

ISO 527

Test in which a sample is exposed to a controlled voltage until it breaks.

Can be used with 1 kN or 25 kN load cell.

Values obtained: E modulus, ultimate tensile strength, breaking strength, total elongation, … -

Impact Test

Charpy Test ISO 179 – Notched/Unnotched Izod ISO 180 – Notched/Unnotched

With the Charpy and Izod impact test, the resistance becomes determined against impact. This because of the impact measuring a pendulum hammer on the sample.

This test can be performed on notched or unnotched (non-notched) samples.

The result, the impact strength is expressed in kJ / m².

-

Flex

ISO 178

A method for determining the bending properties of rigid and semi-rigid plastics

under defined conditions with a load cell of 1 or 25 kN.

Values obtained: flexural modulus, flexural stress at break, flexural strength, flexural stress at conventional deflection, … -

Shore A

Measure hardness on a scale of 0 to 100 of very soft and flexible, to hard and almost non-flexible rubbers. Semi-hard plastics can also be used be measured.

-

Screw Retention

Test to measure the pull-out force of screws fixed into materials.

-

Surface Roughness

The surface roughness of certain applications is important, sometimes a rough surface is desired while for other applications a smooth surface is desired.

-

Surface tension

Surface tension: criterion for the adhesion of printing inks, lacquers, adhesives, etc.

The higher the surface energy of the material is, the better the adhesion is of one on the surface applied fabric.

The test probes contain liquids with a defined surface tension. The surface energy of the material to be checked is simply determined by applying a line with a marker.

The tolerance of the measurement accuracy

is ± 1 mN / m.

-

-

Thermal Tests

-

HDT (Heat deflection temperature)

ISO 75

This test method is suitable for assessing the relative behaviour of different types of material at elevated temperature under load at a specified rate of temperature increase.

-

VST (Vicat softening temperature)

ISO 306

The temperature at which a standard indenting tip with a flat point penetrates 1 mm into the surface of a plastic test specimen is determined. The indenting tip exerts a specified force perpendicular to the test specimen, while the specimen is heated at a specified and uniform rate.

-

TGA (Thermogravimetric analysis)

ISO 11358

TGA is a technique in which the mass of a sample is monitored as a function of temperature and time, while the sample is exposed to a controlled temperature variation up to 900°C.

Thermogravimetry is used to determine the temperature and speed of degradation of a polymer, and at the same time to measure how many volatile substances, additives and / or fillers it contains.

-

DSC (Differential scanning calorimetry)

ISO 11357

Method that measures the difference in energy uptake and release between a sample and one reference, this during a controlled temperature variation (-40 to 600°C).

Is used for determination of melting temperature, glass temperature (Tg), crystallinity, …

Graph that is obtained can be compared via software with databases so as to find out which material is involved

-

OIT (Oxidation induction time or temperature)

via DSC - 11357-6

The time for which, or the temperature up to which, an antioxidant stabilizer system present in a test specimen inhibits oxidation is measured while the specimen is held isothermally at a specified temperature or heated at a constant rate in an oxygen or air atmosphere.

-

Ash Content

(via TGA) – ISO 11358

A sample is heated to 900°C in an oxidative atmosphere. This is a well-proven method to determine the inorganic residue, commonly referred to ash, in organic materials such as polymers, rubbers, etc.

-

VOC (Volatile organic compounds)

Analysis with e-nose

Scents are composed of molecules that have a specific size and shape. When a specific sensor receives the molecules, it sends the signal to a program for processing. Signal patterns are generated and used to characterize odours.

-

-

Optical Tests

-

Color measurement

Used to guarantee consistent quality for both incoming and outgoing quality control. The measuring principle is based on the measurement of spectral reflection within the visible spectrum of 400-700 nm.

-

FTIR (Fourier-transform infrared spectroscopy)

FTIR Analysis measures the infrared spectrum of absorption or emission of a solid or liquid. The basic theory is that the bonds between different elements absorb light at different frequencies. The IR spectrum can be compared with spectrums of a library to check of which material the sample exists.

-

Microscopy

Possibility to enlarge up to 1500x and to measure.

-

QUV Test

ISO 4892

This test reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV tester can reproduce the damage that occurs in the open air after months or years.

-

-

RHEOLOGICAL Tests

-

Melt Flow Index

MFI / MVR – Granules ISO 1133

The MFI is important in the processing of thermoplastics and indicates how many grams of the melt of a particular thermoplastic flow through a tube with a determined length and diameter. The unit of the MFI is g / 10min.

Can be tested with a test load of 0.325 to 21.6 kg from room temperature to 450°C.

-

Roto-Rocket

Tool to visually view and monitor the roto moulding process. Ideal for problems dissolve, test powder flows and experiment with temperature and cycle time.

-

-

Sample preparation

-

Injection Moulding

ISO 294 (Type A1, B1, D2)

Injection of standardized pull and impact bars and plates.

Can with PE, PP, PC, PLA, WPC, NFC, …

-

Compounding

Compounding consists of preparing formulations by mixing, blending polymers and additives to achieve the desired characteristics.

-

Milling

We mill down your granulates to powders, down to sizes as small as 200 microns.

-

Shredding

With our shredding service, we can reduce the size of all kinds of raw materials to any shape ready for processing.

-

Cryo-milling

Cryogenic grinding, also known as freezer milling or cryomilling. The material will be cooled and then reduced into a small particle size. When chilled by dry ice, liquid carbon dioxide or liquid nitrogen, the thermoplastics can be finely ground.

-